Volkswagen Touran Service Manual: Aqua Premium System, Touch-Up System for Three Layer Colors

| Product Description/Objective |

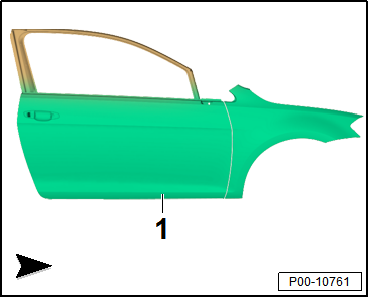

| To achieve an optically flawless color shade transition in

the blended area or adjacent parts, for example fender/door. |

| For plastic surfaces prime with Glazing Adhesion Promoter -ALO

822 000 10- and rework with elastified Two-part HS filler

(Two-Part Plastic Adhesive Filler -LKF 696 009 A2-/-LKF 696 040

A2-). |

|

|

|

| Pre-treatment of base surfaces: |

| |

Clean the factory or old paint or two-part HS filler

thoroughly with Silicone Remover -LVM 020 000 A5- or Silicone

Remover, Long -LVM 020 100 A5-. |

|

|

|

| |

Sand the repair area with P500-P600 grit sandpaper or

wet-sand with water-resistant P800-1000 sandpaper. |

|

|

|

| |

Sand the adjacent area (around the vehicle parts and the

repair area) thoroughly with P1000-3000 sandpaper, only wet

sand. |

Note

| If beading, edges or grip recesses are present, use a

sanding pad beforehand. |

|

|

|

| |

Clean the entire surface thoroughly with Silicone Remover -LVM

020 000 A5- to remove dust, sanding residue and other dirt. |

| |

Wipe off any residual silicone remover with a lint-free

cloth, leaving no streaks. |

|

|

|

| |

Allow wet-sanded surfaces and cleaned surfaces to dry

completely. |

| When using a dust extraction, use next generation towels

with an effective light adhesive formula to minimize the risk of

chemical or adhesive residue (for example, Dust Cloth

-VAS6177-). Refer to

→ Chapter "Dust Cloth -VAS6177-". |

| Insulate sanded-through areas with Two-Part Wash Primer -LHV

043 000 A2- and then fill with Two-Part HS Performance Filler. |

| Test spraying on sheet metal is strongly recommended. |

|

|

|

| Touching-Up Three Layer Colors: |

| Adjusting the touch-up additives: |

| |

Adjust the Touch-Up Additive For Aqua Premium -LVM 035 100

A3- with 10 % Aqua Premium Hardener -LVM 045 000 A1-. |

|

|

|

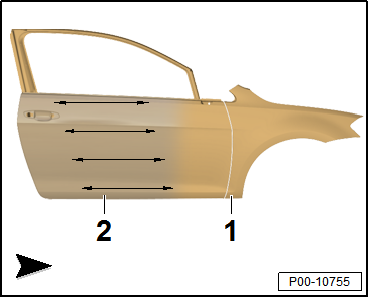

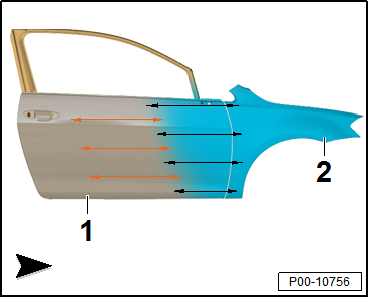

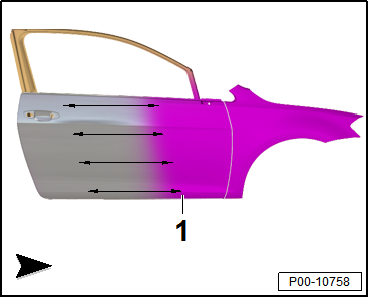

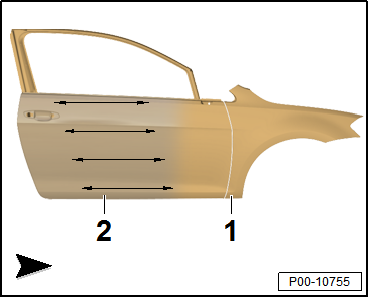

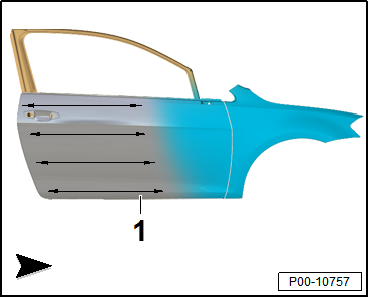

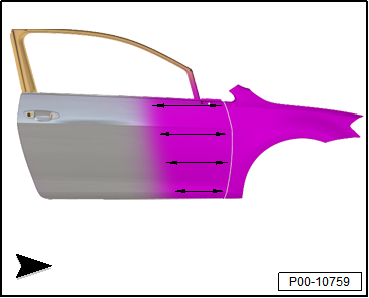

| Repair Process, Touch-up the Neighboring Surfaces (for

Example Color Matching Fender/Door) |

|

|

|

| |

Apply 1-2 preliminary spray applications of the Touch-Up

Additive For Aqua Premium -LVM 035 100 A3--2-

in the blended area with normal spray pressure on the old

paint/filled surface -1-. |

Note

| Pay attention that the blended area is large enough. |

|

|

|

| Adjusting the base color: |

|

|

|

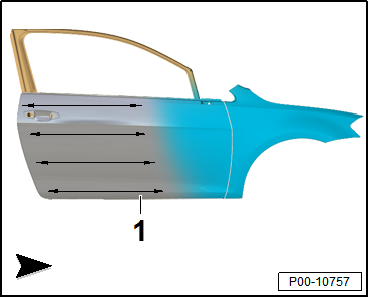

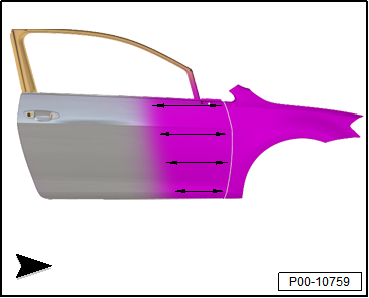

| |

Apply the primary color shade, adjusted for the 5 % Aqua

Premium Hardener -LVM 045 000 A1- and 10 % Additive For Aqua

Premium -LVM 035 301 A3- for solid colors or 20 % Additive For

Aqua Premium -LVM 035 301 A3- for effect colors and adjusted

base colors -2-, onto the repair

area and on the bordering touch-up area up to the covering

capacity. |

| |

While doing so the place the run-out area in the wet

Touch-Up Additive For Aqua Premium -LVM 035 100 A3--1-. |

Note

| For large surfaces, at high temperatures as well as low

humidity an addition of up to 10 % Aquaplus Purified Water -LVW

010 000 A5- is possible. |

| Effect color, 45 to 60 minutes at +20 C (68F) |

| Solid colors, 90 to 120 minutes at +20 C (68F) |

|

|

|

| The ventilation time should take place assisted with blowing

devices at 20-40 C (68-104F) until the surface becomes

completely matted. |

| Allow 5 to 10 minutes of intermediate drying time then 10 to

15 minute final drying time at 60 to 65 C (140 to 149F). Let

the base color shade cool off before applying the effect. |

| Ventilate until the surface becomes completely matted,

without blowing. |

|

|

|

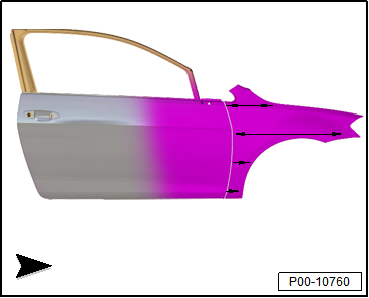

| |

After ventilating apply 1 to 2 preliminary spray

applications of the Touch-Up Additive For Aqua Premium -LVM 035

100 A3--1- in the blended area

without hardener. |

|

|

|

| Adjusting the effect color: |

| |

The effect color is adjusted with 20 % Additive for Aqua

Premium - LVM 035 301 A3-. |

Note

| For large surfaces, at high temperatures as well as low

humidity an addition of up to 10 % Aquaplus Purified Water -LVW

010 000 A5- is possible. |

|

|

|

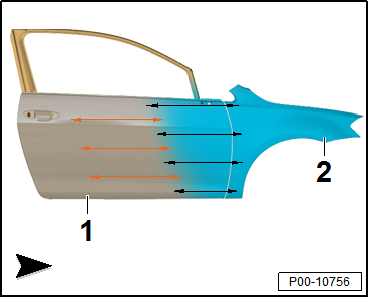

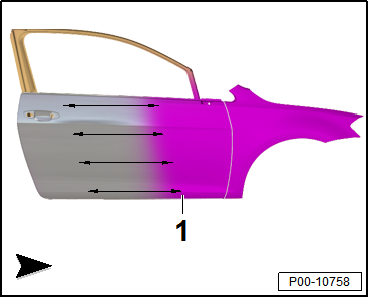

| Step 1, Painting the Effect Color (from the Outside Inward) |

| |

Apply the effect color from run-out area to the to the new

part -1-. This means it is applied

from the outside toward the inside ("wet-in-wet")

in the Touch-Up Additive For Aqua Premium -LVM 035 100 A3-. |

| |

Then if necessary apply the next effect color layer in the

direction of the new part. |

Note

| For some effect colors 2 to 3 additional spray applications

are necessary to match the effect. |

|

|

|

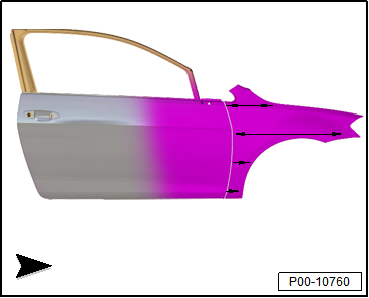

| Step 2, Painting the Effect Color (from the Outside Inward) |

|

|

|

| Step 3, Painting the Effect Color (from the Outside Inward) |

|

|

|

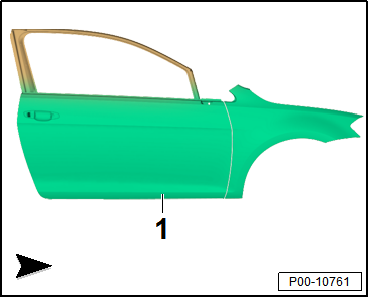

| |

After ventilating, apply a two-part HS clear coat

-1- over the entire repair surface. |

Note

| Starting with the first spray application, it is recommended

to even out the subsequent repair area/base color spray

applications starting from the touch-up area that is farthest

out. For that reason, the subsequent spray applications should

always be remain inside the previous spray application, in order

to avoid visible contours/shadows. |

| While processing the Aqua premium water-based base paint,

the material flow (spray gun trigger) remains completely open. |

| The spraying pressure for the effect spray application can

vary between 1.5 and 2.0 bar depending on the size of the

object. |

| For additional notes to the drying times refer to the

technical application information. |

| Notes for Large Area Applications: |

| Use the Additive for Aqua Premium -LVM 035 301 A3- when

applying 3 coat effect colors. |

| The addition of up to 10 % Aquaplus Purified Water -LVW 010

000 A5- is recommended for large surfaces, high temperatures and

low humidity. |

| For efficient ventilating and drying, stationary blowing

devices or forced drying (for example heated drying) are

recommended. |

| The spray devices should be suitable for use with

water-soluble products; see manufacturer's information. |

| The Aqua Premium mixing paints can only be used within the

color tone formulas. |

| When processing individual mixing paints on their own, major

deviations from the information given in the application

instructions are possible. |

| Rinse before and after using with Aquaplus Purified Water -LVW

010 000 A5-. Then rinse with Nitrocellulose Thinner -LVE 856 000

A3-. |

| Collect liquid waste from water-soluble products and

separate from liquid waste from conventional products. When

mixing materials, disposal may no longer be possible, which is

difficult and costly. |

|

|

|

| Personal Protective Equipment: |

| Note the safety data sheets |

| Wear the personal protective equipment during application |

|

|

|

Product Description/Objective

To achieve an optically flawless color shade transition in

the blended area or adjacent parts, for example fender/door. ...

In order to achieve error-free design and multi-colored

paint applications using Aquaplus solid, metallic, pearlescent

base paint, pay attention to the important note ...

© 2016-2025 Copyright www.vwtouran.net | 0.0103

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Aqua Premium System, Touch-Up System for Two Layer Colors

Aqua Premium System, Touch-Up System for Two Layer Colors Aquaplus Design and Multi-Color Paintwork

Aquaplus Design and Multi-Color Paintwork